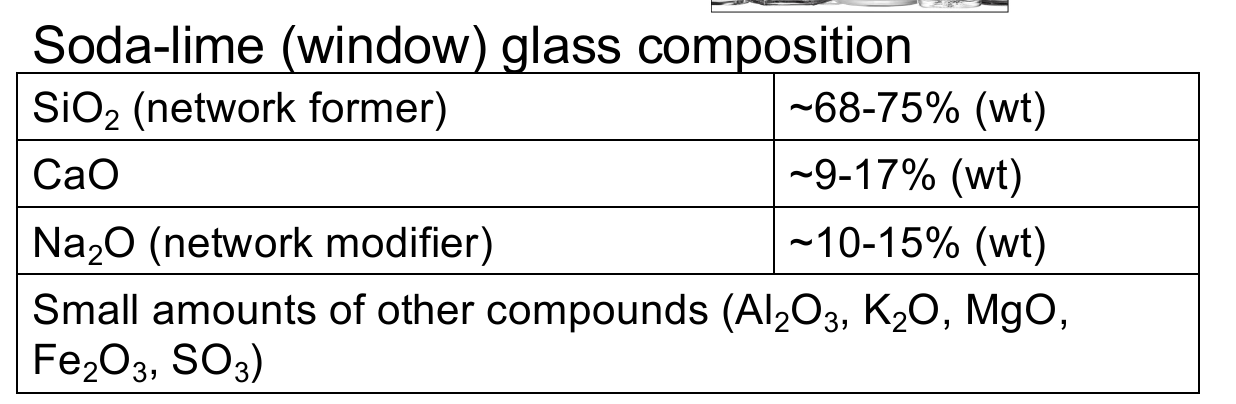

♦Soda-Lime is the most popular household glass product since its easier manufacture ability and contains affordable raw materials. Crushed glass, Quartz, soda ash and limestone are main ingredients. Soduim is responsible for network modifing. While doing this, melting temperature of batch and viscosities are lowering. Those changes leads to decreasing of energy costs and lower viscosity enable to make shaping the product at blowing step is easier. Lime(CaO) is intermediate and added due to prevent dissolving glass in water solutions because of lack of network bindings which caused by alkaline soda.

♦It mostly used in windows, flood and beverage containers. Unlike boron silicate, it has very low thermal shock resistance and higher thermal expansion. When potash added instead of soda ash, glass would be a hard type glass rather than soft glass. Hard glass has more chemical resistance but harder to melt. Additionally, when use lead oxide in batch, it gives more dense structure, more refractive property and superior electrical properties compared to soda-lime.

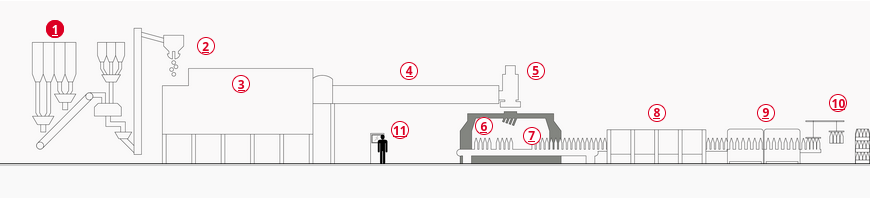

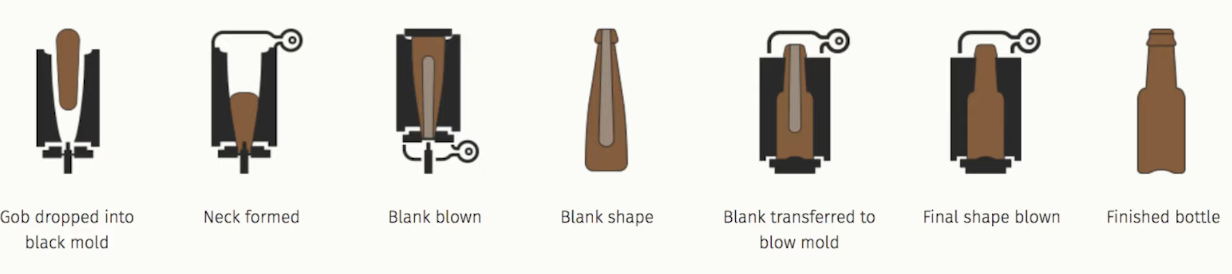

♦(1)Firstly, batch preparation accompany with screening/sieve, drying, or pre-heating for controlling particle size and contamination amount. (2) Decolorizes like MnO2 could be added for bind and remove ferrous and carbon content(or color maker compounds -iron oxide (green), sulphur (amber) and cobalt (blue)- add to batch, if wanted).(3) Melting is up to 1800oC. Natural gas or fuel oil is using for heating. At this melting stage lime and soda ash is fusing and giving reaction with quartz silica. High amount of CO2 is leaving from the batch. At (4), molten glass viscosity is enough to flow with not accumulation and deforming under its own weight, or not forming uneven thinner section. (5,6,7) Shaping is done either blow-blow or press-blow process which is done around 800-900oC and 1.2-3.2 bar pressure. Florine or sulphure gas blowing to decrease pH to desired value.(8) Annealing(580oC) stage is for relieving and removing internal stresses in structure.(9) Coating application is also important against scratches, more lubricity on surface, less reflectivity and chemical interness. Tin(IV)Oxide, TiCl4, and PE(water emulsion) coats are most strenghtening compounds.

♦CaCO3 + SiO2 -> CaSiO3 + CO2(g)

♦Na2CO3 + SiO2 -> Na2SiO3 + CO2(g)

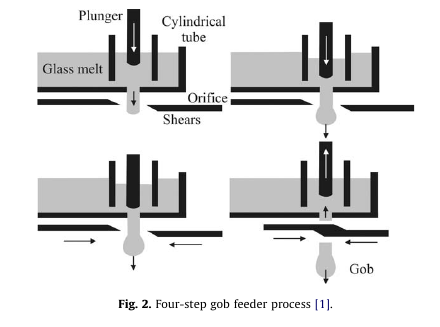

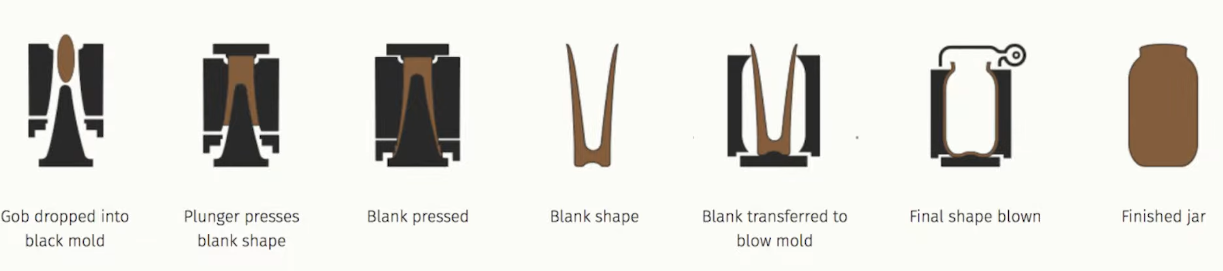

♦Gob is being cut while after melting process. Mass and volume of those gobs should be examined with smart sensors. Temperature and glass flow speed in plunger must be adjusted to overcome sagging deformation especially for light products.(glass could be deformed under its own weight). Moreover, molds should have clean, lubricant and high thermal conductive property. Press-blow is suitable for light products but that process has contamination problems. Blow-blow is for heavy and complex shaped products.(DOI: 10.1016/j.cirpj.2011.02.003)

| Process | Articles |

|---|---|

| Pressing | Culinary and table vessels, pots, lenses, bricks |

| Centrifugal casting (or spinning) | Plates, cathode tubes |

| Blow–blow | Bottles |

| Press–blow | Goblets, light bottles |

| Press–blow–spin | Goblets, laboratory tools |